Downtime is always a threat, machines will fail, what can be done to minimize these failures and drive up OEE?

PMT can provide solutions that help predict those failures early, allowing you the time to plan, order parts and schedule maintenance repairs in a proactive manor.

We can help you create a robust reliability program.

We will use the correct predictive technology suitable to the applications in your plant.

Stop relying on the reactive, fire-fighting maintenance measures of the past and start a proactive approach. With PMT you will have the ability to predict and prevent failures before they occur.

PMT can set up surveys and databases using SDT ultrasound and Flir IR. We can check assets on a schedule that maximizes the time between failures and helps minimize unscheduled downtime.

We can provide greater insight into the health of your assets. We can help you control energy costs, predict failures, improve product quality and increase overall production uptime. We can perform commissioning baseline data collection on your initial startup or on recently replaced equipment.

Bearing Monitoring

This is one of many ultrasound applications that gauge the health of your plant. All bearings emit ultrasound signals that are masked by the sounds of your operation. Ultrasonic bearing monitoring enables us to hear, measure and trend these signals and decide if your asset is OK. Identifying early-stage bearing defects will prevent unplanned failures. Incorrect fit, improper installation and over/under lubrication can be detected using ultrasound.

Rotating equipment

We can detect coupling defects/failures and misalignment issues using ultrasound. Motors, pumps and gearbox condition can be checked and trended in the database software. Pump cavitation is also easily detectable using ultrasound. Chains, sprockets, sheaves, drive belts and pullies also emit ultrasound that can be trended and used to determine the condition without intrusive PM’s.

Leak Detection

Each day that a leak goes undetected is another day of wasted resources, increased energy costs and diminished product quality. Locating compressed air leaks in noisy production areas is nearly impossible. PMT’s compressed air leak management program will find the air leaks in your plant. Repaired air leaks could cut your energy costs by 40%. We can perform air leak surveys, find the leaks, record the size and cost, tag them and create a report that can be passed on to the maintenance planner for scheduling .

Electrical Systems

PMT uses ultrasound to hear what you cannot see. Electrical discharge is a constant threat to your safety and the health of your electrical systems. We can scan your electrical systems for partial discharge faults. Ultrasound can reveal electrical fault conditions such as partial discharge (corona), partial arcing (tracking) and arcing discharge inside metal clad switchgear, around substations, and in overhead transmission and distribution lines.

Steam Traps

We can Identify failed steam traps that reduce system efficiency. Your steam traps contribute to product quality, energy conservation, component longevity and employee safety. Yet it is not uncommon to have as much as 50% of steam traps in a failed state.

Steam traps that function properly help maintain purity and efficiency throughout the system.

Valve Monitoring

When your valves are closed, are they really closed? How can you be sure? When a valve isn’t completely closed it creates ultrasonic turbulence at the source of the leak. Using ultrasound we can hear that turbulence over the noise of the factory.

Whether it’s internal or external leaks, or issues with flow regulation, valve leaks are a threat to your process. Efficient processes depend on having valves that perform their function properly. Regular ultrasonic inspection quickly identifies which valves are leaking and which ones are closed.

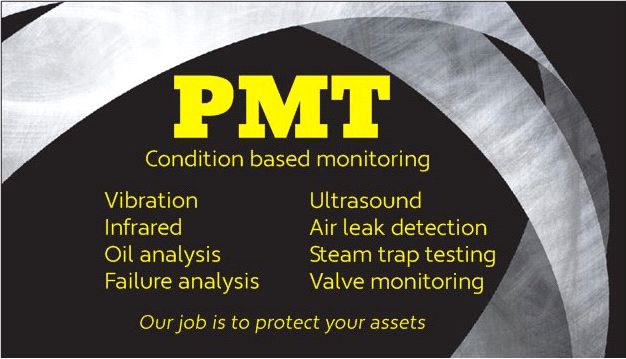

Condition Monitoring

Keep a pulse on the condition of your plant’s assets. Condition-based maintenance represents a change to the way maintenance tasks are scheduled. Instead of performing calendar-driven tasks, maintenance is carried out only when the condition of an asset changes. PMT can provide you with data about the health of both rotating and non-rotating assets, warning you well in advance that a failure is in the future.

Precision Lubrication – Most bearings do not live to their engineered lifecycle, and bad lubrication practices are the leading cause. Lubrication of bearings is one of the most misunderstood and abused tasks in the industry. Knowing when and how much to grease is the key to optimizing bearing lubrication. With ultrasonic bearing monitoring, we are able to lubricate bearings based on their condition rather than on a fixed schedule. Predict re-lubrication intervals and add just the right amount of grease with integrated ultrasound greasing solutions. Lubricate bearings based on their condition rather than on a fixed schedule.

Asset and bearing forensics

We can perform inspections and forensic analysis on any failed asset or rotating equipment to determine the root cause of failure. With this information you can start or add to your FMECA database, make changes to your maintenance program or make engineering and design modifications.

Oil analysis

We can perform routinely scheduled or specific oil sampling on equipment to confirm condition. Gearboxes, blowers and hydraulic systems are commonly tested. We use a certified lab to provide you with the information you need such as but not limited to: wear metals, such as iron from gears, contaminants, such as lithium, which indicate the presence of grease, oil additives, like phosphorus, which is found in extreme pressure and antiwear additives.

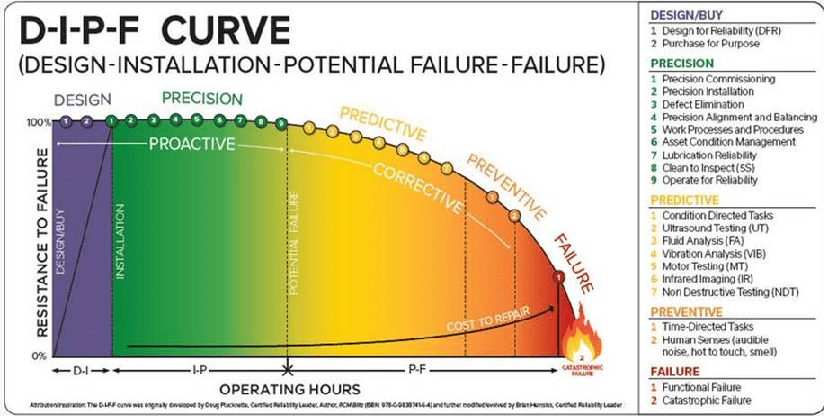

Infrared thermography

IR Thermography can find and measure hidden electrical and mechanical problems. Mechanical infrared enables us to monitor bearings, steam traps and rotating equipment. Electrical inspections can discover motor bearing and winding temperature issues. This is often used in conjunction with the ultrasound surveys and precision lubrication routes. This can be used when assets are guarded or in a unsafe area or on equipment where it is not cost effective to use ultrasound monitoring. Reports can be generated with analysis and recommendations.

Troubleshooting

Using IR and ultrasound we can help pin point suspected failing components to minimize changing a wide range of parts unnecessarily.

Reports

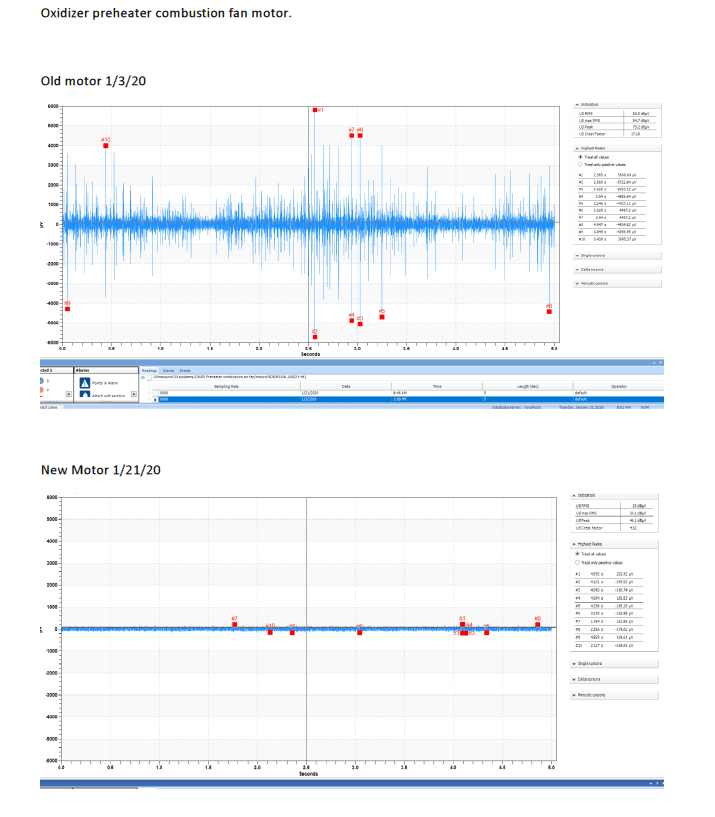

We will provide reports on the condition of the monitored assets and rotating equipment. Asset condition reports can be straight forward and not complicated. Ultrasound reports can contain audio files, Dynamic spectrum analysis and time waveform graphs for more in-depth analysis and reliability centered maintenance programs.

Forensic reports can be provided on any failed component or part.

Marine Applications – Ultrasonic tightness testing on hatch covers.

Tank Test – Reveal leaks in storage tanks. Compliance with the method procedures ensures diagnosis accuracy (“tight or not tight”) traceability and data for each inspection. Reports include recording of dBμV measurements and audio files.

ATEX Certified

One of the technologies we use is the SDT270 ultrasound detector. It meets the requirements set by ATEX for use in the most dangerous and potentially explosive atmospheres in the world.

Please feel free to contact me directly for information on our programs, technology and pricing. I would be happy to visit your facility and demonstrate what we can do.

Paul Klemke

360-201-3987

Predictive Maintenance Technology L.L.C.

159 James Way

Old Town, Idaho 83822

Pklemke@hotmail.com

PredictiveMaintenanceTech@gmail.com